Many industries are adopting 3D technology due to its many problem-solving capabilities.

More and more, diverse companies are adopting 3D technology to enhance problem solving. From 3D scanning to 3D printing, here are three ways in which 3D technology is transforming several industries and emerging as a premier solution.

Novel Medical Solutions for Healthcare Organizations

According to a study by researchers at Johns Hopkins Medicine, medical errors are the third-leading cause of death in the U.S., killing more than 250,000 Americans each year. Surgical complications are among the types of medical mistakes that can lead to death. Historically, a surgeon would have developed his or her skill set by operating on human cadavers, animals, and actual patients. Cadaveric models mimic the surgical technique applications and anatomy better than animals, but financial cost and lack of availability present barriers to the use of cadavers.

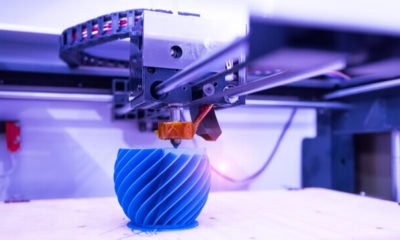

Healthcare technology startups have responded to the problem by reproducing organs and other simulation models using 3D printers. The ability of 3D printers to produce high-quality anatomical models that behave very similarly to real, human tissue is driving medical training programs to adopt this technology. As a result, both novice and expert surgeons have greater access to opportunities to acquire and improve surgical techniques. 3D printing can be a particularly beneficial tool for mastering necessary technical skills to perform new and complex procedures, as it enables repeated practice in a setting that forgives failure.

Improving Problem Solving in the Classroom

Advances in computing technology have also changed the way students are learning in the classroom, with more teachers harnessing the power of 3D technology. Visual learning plays an important role in student performance in several areas, including retention and recall of information and problem solving. 3D technology can enhance the visual learning process and bring lessons to life, transforming difficult subjects into engaging, 3D experiences.

For instance, virtual environments can allow students to step into dense clouds suspended in Earth’s atmosphere or explore the structure of an atom complete with animated electrons spinning around the central core of protons and neutrons. Providing students with realistic and immersive visual aids enables students to increase their knowledge and understanding in a more effective manner than textbook learning, improving the quality of education in classrooms.

Increasing Efficiency in Design and Manufacturing Processes

As the technology matures, engineers and technicians are increasingly leveraging 3D scanning in the design and production process to streamline operations and reduce costs. For instance, engineers are reverse engineering physical objects with 3D scanners, as 3D scanners can bring objects into the 3D, digital environment more efficiently than conventional design methods. Traditionally, reverse engineering is a time-consuming process performed by hand using measurement tools, such as calipers.

In addition to the difficulty inherent to this method, hand measurement is prone to inaccuracies. A 3D scanner can rapidly capture information about a physical object and convert that information into a usable, digital format with a high degree of accuracy, presenting significant benefits to engineering settings. Many scanners on the market today are designed to capture intricate details and textures of an object’s dimensions and material properties for the purpose of reverse engineering. 3D scanning is also ideal for prototyping applications and quality assurance as it can reduce the number and length of design cycles and quickly manifest CAD models to compare against a prototype.