Dating back to 1983, 3D printing has since revolutionized the course of printing, into something dynamic. While it has been used in quite a plethora of sectors such as advertising, animation, and health, to name a few, there is a particular reason why most people choose to make use of it, over the rest.

In this article, let’s look at 12 types of 3D printing and why 3D printing is important.

But first, what is the importance of 3D printing[1]?

IMPORTANCE OF 3D PRINTING

People love 3D printing because of the edge it has over others. And the edge it has over the rest can be clearly seen in how often the final texture appears on your model in real-time. That is, with 3D printing, unlike the 2D and the rest, you can add finer details to smaller areas of your texture easily, using software like Adobe Photoshop.

Quite frankly, we both know that you can’t achieve this easily on a 2D printing, and that’s why so many people love it. So, what are the types of 3D printing available?

TYPES OF 3D PRINTING

-

Stereolithography (SLA)

Being the first 3D technology to be introduced, stereolithography (SLA) is a stereolithography laser melting technology that came into existence when Chuck Hull, filed the patent on this technology and started 3D Systems as means of commercializing the 3D printing machine in the year 1986. Generally, this 3D technology is used if you’re seeking to obtain more precision and accuracy in your printing.

-

Digital Light Processing (DLP)

DLD mode of technology is quite similar to SLA, with the only difference being in its machine which uses light-emitting diode (LED) screens to project light onto a resin, directed to build a surface from a Digital Micromirror Device (DMD). This is why DLP flashes the picture of every layer with its digital light projector after each layer is complete.

-

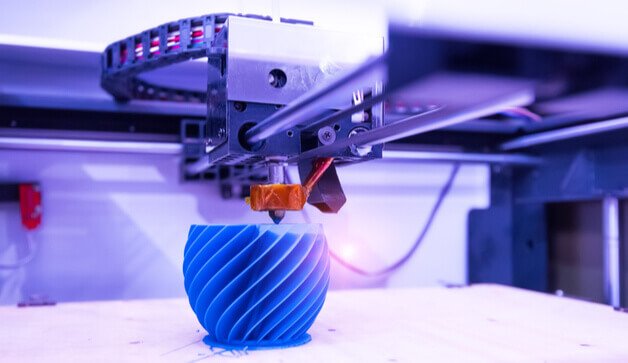

Fused Deposition Modelling (FDM)

Being known to be the most common 3D printing technology, the Material extrusion devices, which is often known as Fused Deposition Modelling (FDM), or Fused Filament Fabrication (FFF), works when a filament spool is placed in the machine, and then passed through the printer nozzle to the extrusion head. In this technology, the nozzle of the 3D printer has to be heated to the right temperature, while simultaneously using the motor to push the filament through the heated nozzle to melt it. This form is ideal, if you’re seeking to get the real form of your object.

-

Selective Laser Melting (SLM)

Commonly used to facilitate easier creation of metal alloys, Selective Laser Melting (SLM), is an additive manufacturer that prints metal alloys through the combination of metal powder particles, under the complete melting process.

-

Selective Laser Sintering (SLS)

Formed and patented by Dr. Carl Deckard, an American inventor teacher and businessman in the 1980s, the Selective Laser Sintering (SLS) 3D printing technology uses high power CO2 to fuse together powder particles. Although it can make use of other forms of materials such as white nylon powder, ceramics, and glass, its machine has a platform that gradually stores every successive laser scan.

-

Electronic Beam Melting (EBM)

Founded in 1997, EBM 3D printing technology[2] is quite similar to the SLM technology because they both rely on the powder fusion method, with the only difference being in their power source where; the SLM utilizes a high-powered laser in a nozzle chamber, while the EBM makes use of high power electron beams in a vacuum. Other than the power source, they are both similar.

-

Laminated Object Manufacturing (LOM)

Otherwise known as Cubic Technologies, Laminated Object Manufacturing (LOM) is among the most potent and highly affordable 3D printing technologies. Patented by Michael Feygin, a United States engineer, the LOM is a fast prototyping system that works by laminating and fusing each layer of paper, and plastic through pressure and heat. It is widely known for its utmost speed.

-

Material Jetting (MJ)

MJ is more like the standard inkjet printer, with the only difference being that unlike the standard inkjet printer, which prints single layers of ink, MJ, on the other hand, builds multiple layers to make a solid object.

-

Drop on Demand (DOD)

DOD 3D printing technology[3] makes use of two inkjets where; one inkjet installs the building material (wax-like materials), and the other inkjets install the dissolvable support materials. And as you’d expect, DOD printers work by clinging to predetermined paths, in order to deposit the material and make cross-sectional object area layer after layer.

-

Sand Binder Jetting (SBJ)

Binder jetting is a 3D manufacturing process that involves the deposition of binding agents to join powder particles. The manufacturer then bonds the layer materials to make the object.

-

Metal Binder Jetting (MBJ)

Known to be the most economical, MBJ build size is bigger, and the production parts do not need any supporting structures while printing. So, if you’re looking to economise cost, this is the ideal 3D technology.

-

Bioprinting (BP)

Applicable in the medical and bioengineering field, BP another form of additive manufacturing process houses a combination of biomaterials, which makes use of ink materials to create structures, in a layer after layer manner.

In a nutshell, 3D printing is the future because, with it, you can economise and alter any structure to your desired taste, while still arriving at a high-end design.