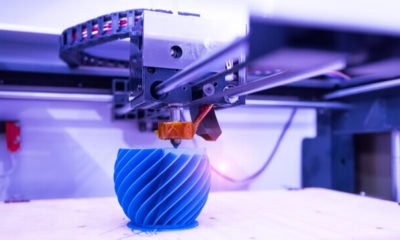

3D printing and the mixture of elegant materials into printable objects have led to the expansion of an electrifying new technology called 4D printing.

This article will explore the current status and potential applications of 4D printing. Let’s talk about 4D printing applications, about the water reactive 4D printing method, temperature immediate 4D printing, modeling and simulation software, and the future of 4D applications.

Smart materials that react to diverse exterior stimuli are described, along with the profit of these smart materials and their potential use in 4D printing applications, specifically, as existing light-reactive smart materials.

4D printing has the potential to shorten the design and manufacturing of unlike products and the possibility of automating actuation devices that obviously react to their surroundings without the requirement for human communication, batteries, processors, sensors, and motors. This tool can also be used to generate drug capsules that release medicine at the first sign of an infection. “We eventually desire to use body temperature as a start,” says Nicholas X. Fang, associate professor of mechanical engineering at MIT. “If we can design these polymers correctly, we might be able to shape a drug delivery tool that will only discharge remedy at the sign of a fever.” Researchers say 4D printing tools could have extra medical applications such as stents that expand after being uncovered to high temperature. The work derives from a plan to develop high-performance 3D printed carbon fiber composites. 4D printing applications are a fascinating way to enable configuration switching in 3D printed items.

Current Status of 4D printing

Currently, four major approaches, namely self-assembly of elements, deformation mismatch, bi-stability, and the shape memory effect, are identified as the generic techniques to achieve 4D printing. Utilizing one or more of these approaches, the potential of 4D printing to reshape product design is demonstrated by a few sample 4D printing applications in biotechnology.

4D printing in biotechnology is an advanced technique, where a time of usage is also integrated with a 3D bio-printing, in which printed medical models become capable of changing their shape and functionalities. This time-dependent shape model also provides a high potential for biomedical scaffolds and various other essential purposes. It has various emerging applications in medicine as well.

4D Printing applications in medical

In medical, there is a requirement of accurate detail of anatomy which can improve clinical outcomes, shorten the effective length, reduce donor site morbidity, and decrease overall operative complications. 4D printing has a high potential in biomedical applications like self-bending stents and other self-shrinking/tightening staples.

4D printing technology has the potential to change the surgeon approach for diagnostic and treatment planning in orthopedics. Today 4D printing in medical replaces conservative scaffold manufacture methods, and the primary purpose of this technology is to make implants with unique geometrical individuality and features with higher legibility to change the shape of the model. This emerging technology will become more beneficial and help to create endless possibilities in the medical field.

In future years, 4D printing technology will make a disruptive effect on health, engineering, and other fields. In medicine, every model is customized and differs from patient to patient. 4D printing technology is a better technique and offers quality, efficiency, and performance allowing individual patients to easily print medical materials in less time which has major benefits for humanity.