In high schools in America, it used to be common for students to take a hands-on learning course called “wood shop.” In wood shop, a student would learn how to create basic things out of wood.

A favorite project for wood shop is to make salt and pepper shakers. For this project, students take a wooden cylinder, cut it to the correct length, hollow it out by drilling into the center, and then put it on a rotating wooden lathe to shave off a part of the cylinder to make a decorative shape. This is fun and easy to do.

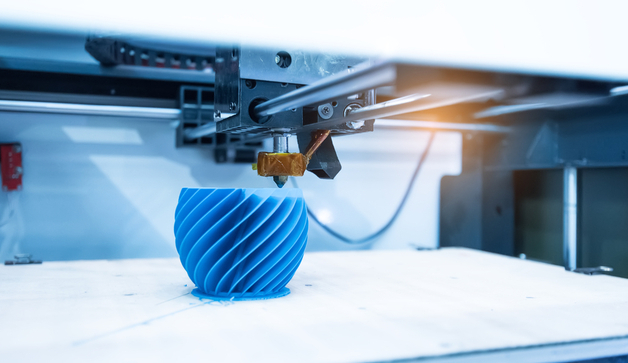

Fast-forward to contemporary times and the technological advancements of 3D printing. With this new technology, we have a modern version of crafting equipment that is even better than the old-fashioned wood shop. With 3D printing technology, a person can now do amazing projects and do them at home. If you are the kind of person who thinks wood shop sounds fun, then 3D printing is even more fun.

Home 3D Printing

When 3D printers first came out, they cost a small fortune. As with most technology, as the market demand increased and the volume of sales went up, the price of the technology came way down. It is possible now to get a great 3D printer for home use for under $1,000. Many good choices sell for less than $500. Even professionals, who work with commercial-grade 3D printers, will enjoy having one of these low-cost 3D printers at home.

Popular 3D Printing Techniques

All 3D printing technology works based on an additive process where thin layers of materials are added to each other. However, depending on the materials used and the end results desired, there are different cool techniques that can be done at home. Material choices include plastic, alumide (nylon with aluminum dust), resin, wax, metals, and paper. For some 3D printers, the materials used can only be monochrome (one color). More sophisticated 3D printers can make objects in multiple colors.

Our five favorites techniques are:

- For Plastic and Alumide: Fused Deposition Modeling (FDM)

- For Resin and Wax: Digital Light Processing (DLP)

- For Metals: DLP Combined with Lost-Wax Casting

- For Paper: Selective Deposition Layering (SDL)

- For Multicolor Plastic: Multi-Jet DLP

Fused Deposition Modeling

Fused Deposition Modeling (FDM) was the first technique used for 3D modeling. It is the most common form used to print objects out of plastic. It is a very affordable method. The plastic material is melted and then extruded through a nozzle. It is deposited as layers that build upon each other as the bed holding the object automatically lowers.

Digital Light Processing

Digital Light Processing (DLP) uses a special light to cure a photopolymer resin material. The item is made by shining this light on the resin in a pattern that represents the item that is created one layer at a time. The object either rises out of the uncured resin, one layer at a time, or is pulled down into the uncured resin with the next layer being cured on the very top.

DLP Combined with Lost-Wax Casting

Creating objects out of metals, such as brass or silver, is a three-step process. First, a wax model is made of the object. Second, a strong mold is made around the wax from a material that can withstand molten metal. Third, the wax is melted, and molten metal is poured into the top of this mold to create the object.

Selective Deposition Lamination

Selective Deposition Lamination (SDL) uses paper. Layers of paper that have adhesive on the back are glued together one sheet at a time using a heated roller. The shape is cut by a laser for each layer as the object is built up.

Multi-Jet DLP

Multi-jet DLP is the same technique as regular DLP except that the 3D printer has more than one jet to deposit resins of different colors. After the first layer is printed, the resin is exposed to a special light that fixes it and changes it to a solid layer. Much like a regular dot-matrix inkjet printer, each layer has the microdots of resin deposited in different colors that are placed in the right proportions to create many combinations of attractive colors.

LP is the same technique as regular DLP except that the 3D printer has more than one jet to deposit resins of different colors. After the first layer is printed, the resin is exposed to a special light that fixes it and changes it to a solid layer. Much like a regular dot-matrix inkjet printer, each layer has the microdots of resin deposited in different colors that are placed in the right proportions to create many combinations of attractive colors.

With all the great options for using 3D printers at home, it is anticipated that their deployment will be massive. So many homes have a regular printer. Having a 3D printer at home should become as popular.

Fun things to create at home include unique pieces of art, spare parts that are not otherwise available, all kinds of custom things and handy tools. You don’t even need to be able to create the 3D models that the 3D printer software needs to use. Many cool ones are readily available for download online. And yes, you can make cool salt and pepper shakers with a 3D printer. Let’s get printing!