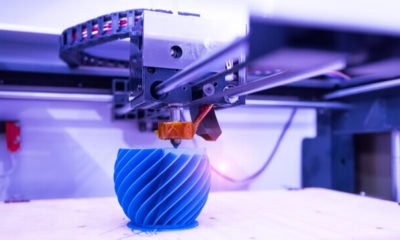

A research group from the City University of Hong Kong has recently developed the first 4D printer for ceramics. This 4D ceramics printing process can be used on complex shapes. Ceramics have a high melting point which makes the material hard to shape and form into complex shapes. To tackle this problem, the City University team developed a ceramic ink. This ink has a combination of polymers and ceramic nanoparticles. It can be used to print and shape ceramics.

This 3D ceramic precursors in this ink are soft and malleable. They can be stretched three times longer than their original length. This flexibility allows complex shapes like the art of origami folding. With proper heat treatment, ceramics with complex shapes can be created. The team was led by Professor Jian Lu, Vice President of Research and Technology at City University. He is Chair Professor of Engineering and a materials scientist who has researched fabricating nanomaterials, advanced materials, and computer simulations of surface engineering models.

Their team has developed two breakthroughs on 4D printing with ceramics. 4D printing is 3D printing with the added element to time and that the object can be reshaped or reassembled using mechanical force, temperature, or a magnetic field in the process. The elastic energy that is stored in the stretched precursors can be reshaped, and with heat treatment turn into ceramics.

These ceramics are mechanically well made. They have a high strength to density ratio, and they can be made in large sizes that are strong compared to other printed ceramics. The process may sound simple, but it was not, Professor Lu said. The team tried several many times, and several different methods to make the ink and printing system. It took them two years to overcome these problems and develop a 4D ceramics printing system.

Professor Lu says the process was like squeezing icing on the cake because many factors can affect the outcome of the work. These factors can be the size of the nozzle, type of cream used, temperature, and force that you squeeze the bag. In one of the first printing that they tried they used the new ink; the substrate was stretched by using a stretching device that was biaxial. The joints that would be used to connect the precursor were printed on it.

This stretched precursor was placed on the stretched substrate. Using computer modeling to control the element of time, and the release of the stretched substrate these materials changed into the designed shape. In their second attempt, they printed the pattern directly onto the stretched ceramic precursor. It underwent computer programming and eventually changed shape.

This 4D printing breakthrough was printed in a top scientific journal titles Science Advances. The article was titled, “Origami and 4D Printing of Elastomer-Derived Ceramic Structures.” The team of researchers was Dr. LU Guo, Research Assistant; Dr. ZHAO Yan, Senior Research Assistant; and Dr. Wu Ge, Research Fellow. The team was led by Professor Jian Lu.

4D ceramic printing has the potential to be used in several industries including telecommunications, electronics, and space exploration. This process can be used with electronic devices because they transmit electromagnetic signals better than other materials. With 5G networks, ceramic material plays an essential role in the manufacturing of electronic products.