One of the most stable and traditional industries has been the supply chain. For the last hundred years at least, good has moved from production to supplier, to customer without much interruption in that chain. That is until 3D printing tech came on the scene. The impact of 3D printing in the supply chain has already been enough to move investors and get major companies like Amazon to notice. With the popular use of 3D printing technology being only a few years old and already having a major impact, how will 3D printing shape the future of the supply chain?

One of the best ways to understand what’s going on with 3D printing and the supply chain is to look to another, a similar technology that had a major impact on the supply chain over two decades ago. Before the internet, customers would have to physically travel to their suppliers. While mail ordering and phone calls were common, they lacked the efficiency of the coming internet. The lag in the movement of information slowed down production and the supply chain. Once the internet hit the scene, things began to change.

Now customers could go to their supplier’s website and make their orders from there. Once digital graphics and video technology caught up, customers could even examine well before making a purchase. The long and short of this is, the supply chain cut out some physical travel and sped up production. We can already see the benefits of 3D printing in supply chain mirroring the changes brought by digital communications.

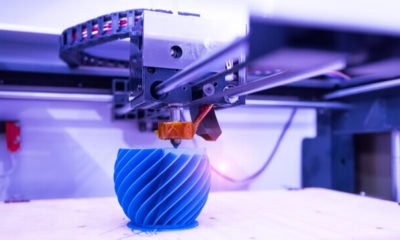

The first thing to consider is that people are already bringing 3D printing technology into their homes. This isn’t going to be another supplier-side technology that will have an impact, but a limited one. This is going to be a major shift. Just like internet cut out a major physical distance, so will 3D printing. Now products can be both ordered digitally and shipped digitally.

Imagine ordering a new set of ceramic knives off Amazon and it starts printing into your home seconds after you hit “order.” No shipping needed. For larger suppliers, a battery of 3D printers stands to displace large sections of their shipping overhead. As the price of 3D printing continues to drop, we are likely going to see this trend continue. It’s not just the speed and presence of 3D printing that makes it a game changer.

3D printing in supply chain markets is set to have another major impact. Currently, 3D printing is still taking shape. The most common application is small plastics. This is already a massive section of the economy, but the trajectory doesn’t end here. 3D printing researchers are working on ways to print everything from ceramics to fabrics, to human organs! Bioprinting, as it’s called, is currently making huge strides toward disrupting how we ship, and even understand donor organs. There aren’t going to be many sectors that aren’t impacted by the rapid growth in 3D printing technology.

3D printing technology is currently just taking off, but it’s already made some impressive waves in the supply chain. We’re seeing a disruption like the one that began with people bringing the internet into their homes—a true game changer. 3D printers are becoming ubiquitous with hobbyist models already lower than $500 and expected to drop. The researchers interested in 3D printing are also hard at work experimenting with the different supply chains that this technology can help to streamline. If these trends continue as expected the concept of ordering “digital goods” is going to take on a whole new meaning.